Thailand’s First Neat SAF Production Unit

In this edition of Executive Talk, we take a closer look at Bangchak Corporation’s new role as Thailand’s first mover in the Neat SAF (Sustainable Aviation Fuel) business. This milestone highlights the company’s leadership in energy innovation, built on over two decades of experience in developing renewable energy—guided by the visionary leadership of

Mr. Chaiwat Kovavisarach

Bangchak Group Chief Executive Officer and President

From a Renewable Energy Leader to a Future Energy Pioneer

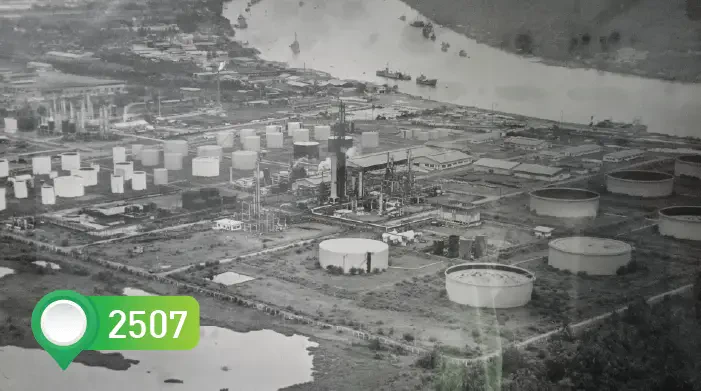

In 1964, the Energy Department of the Ministry of Defence began operating an oil refinery in Bangchak Subdistrict, Phra Khanong District, Phra Nakhon Province. The operation was managed under a 15-year lease agreement with Summit Industrial Corporation (Panama). In 1982, the facility was renamed the Bangchak Military Refinery.

Later, in 1984, Bangchak Petroleum Company Limited was established to strengthen national energy security and help improve the quality of life in Thai society.

From oil refining, Bangchak expanded into the marketing business. In collaboration with Sri Prachan Agricultural Cooperative in Suphan Buri Province, the company launched Thailand’s first “cooperative station” or “community service station” under the “Oil for Rice” initiative in 1990.

The program enabled farmers to access high-quality fuel at fair prices while receiving returns through the cooperative system. It became one of Thailand’s earliest models of community enterprise and has now expanded to more than 600 stations nationwide.

Meanwhile, Bangchak continued to pioneer new alternative energy initiatives. In 2000, it provided critical support for a biodiesel production initiative within the Chitralada Royal Project in collaboration with the Royal Thai Naval Dockyard, laying the foundation for Thailand’s biofuel development. In 2006, the company began buying used cooking oil from communities and partner networks for biodiesel production, and in 2016, it expanded into ethanol production.

In 2025, Bangchak is opening a new chapter as Thailand’s first producer of Neat SAF, building on over 20 years of experience in collecting and transforming used cooking oil into biofuels. The company has established the country’s first stand-alone Neat SAF production unit at its Bangchak Phra Khanong Refinery, producing 100% SAF from used cooking oil and other alternative feedstocks. This effort supports the growth of Thailand’s Bio-Circular-Green (BCG) Economy.

Khun Chaiwat stated that this is Thailand’s first fully integrated standalone Neat SAF production facility. The unit oversees the entire value chain—from feedstock procurement and processing to product distribution—under the International Sustainability and Carbon Certification (ISCC) scheme. With an initial production capacity of 1 million liters per day, the facility employs Hydroprocessed Esters and Fatty Acids (HEFA) technology, processing fatty acids or vegetable oils, such as used cooking oil, into high-quality SAF. The production process was developed in collaboration with two global technology leaders: Desmet of Belgium, specializing in pretreatment technologies, and UOP Honeywell of the United States, a pioneer in hydroprocessing systems. This collaboration ensures quality control across all stages, including feedstock handling, hydrogenation, molecular restructuring, and fractionation, resulting in SAF that meets ASTM aviation fuel standards. The facility primarily produces Neat SAF, with byproducts such as Bio-LPG and Bio-Naphtha, and is currently undergoing Plant Performance Test Runs.

On top of that, Bangchak has developed a sourcing mechanism for used cooking oil through its “Fry to Fly” program by purchasing used oil from households through over 290 Bangchak service stations nationwide, with a target to expand to 2,000 stations by the end of 2025. This includes building cooperative networks for raw material procurement with government agencies and business partners across various industries, including restaurant networks and food establishments nationwide. The program ensures the oil is properly and safely integrated into the SAF production process. It also helps remove reused oil from the food system, mitigating public health risks, while preventing improper disposal into waterways and promoting responsible waste management. Additionally, Bangchak has partnered with both public and private sector organizations to promote SAF adoption through comprehensive collaboration, ranging from feedstock sourcing to production and application in aviation. These partnerships are helping to accelerate the country’s energy transition and support collective Net Zero goals.

Mr. Chaiwat Kovavisarach

Bangchak Group Chief Executive Officer and President